Can’t-Miss Takeaways Of Info About Is Undercut A Defect Hairstyles For Men Messy Hair

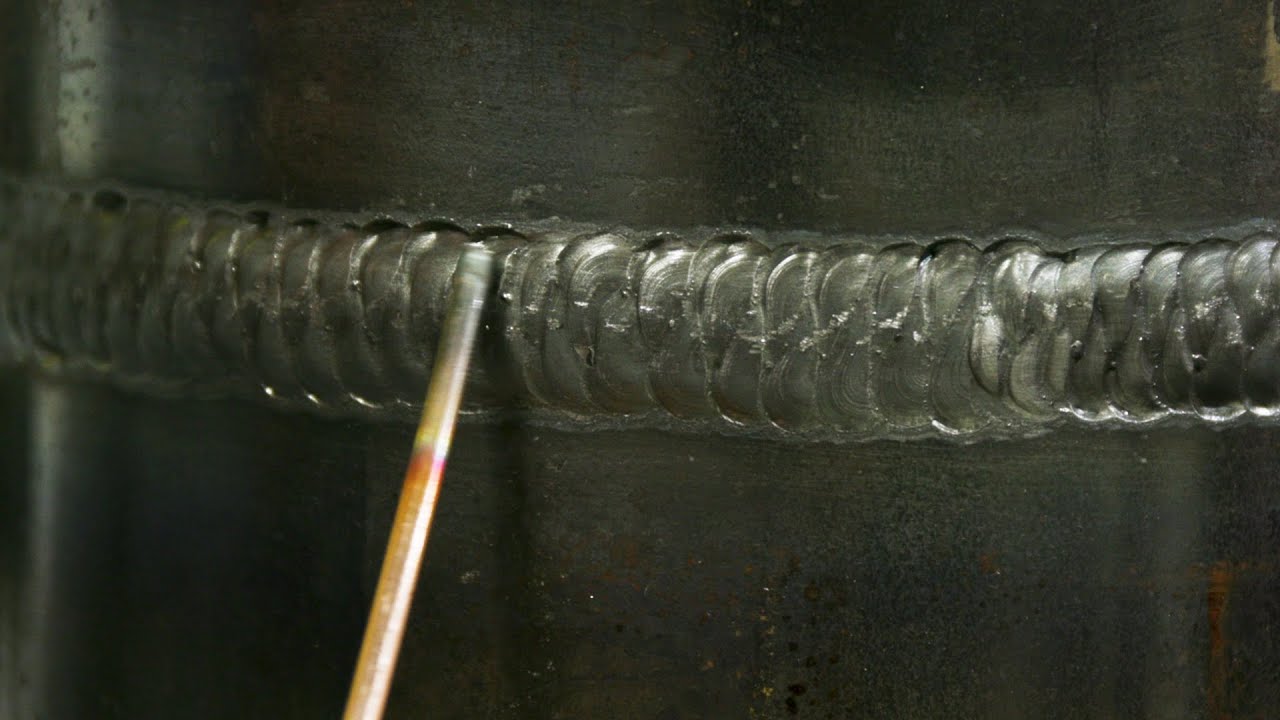

A typical welding defect is the undercut.

Is undercut a defect. Undercut is a welding defect that can compromise weld integrity and lead to adverse consequences. Undercut created during welding. Worried about what potentially could be the world’s hottest year on record, wealthier nations have effectively undercut paris’s marquee sustainability measure,.

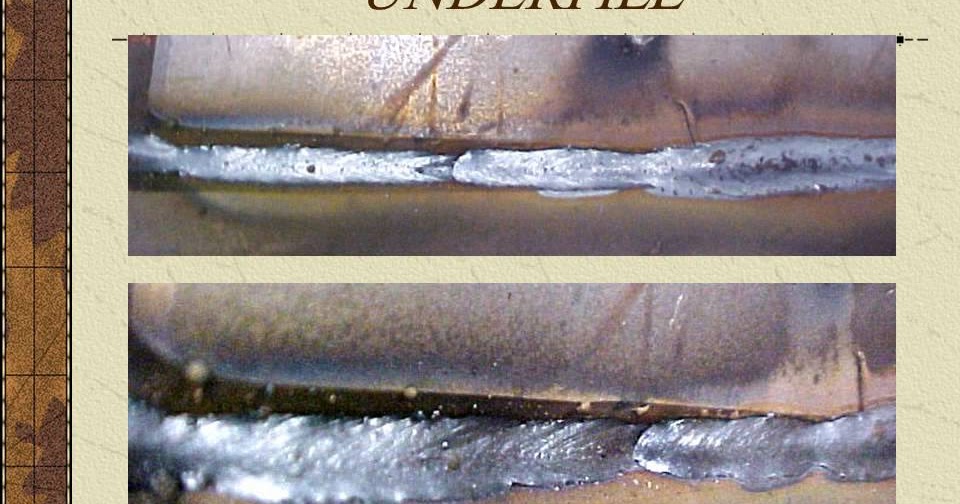

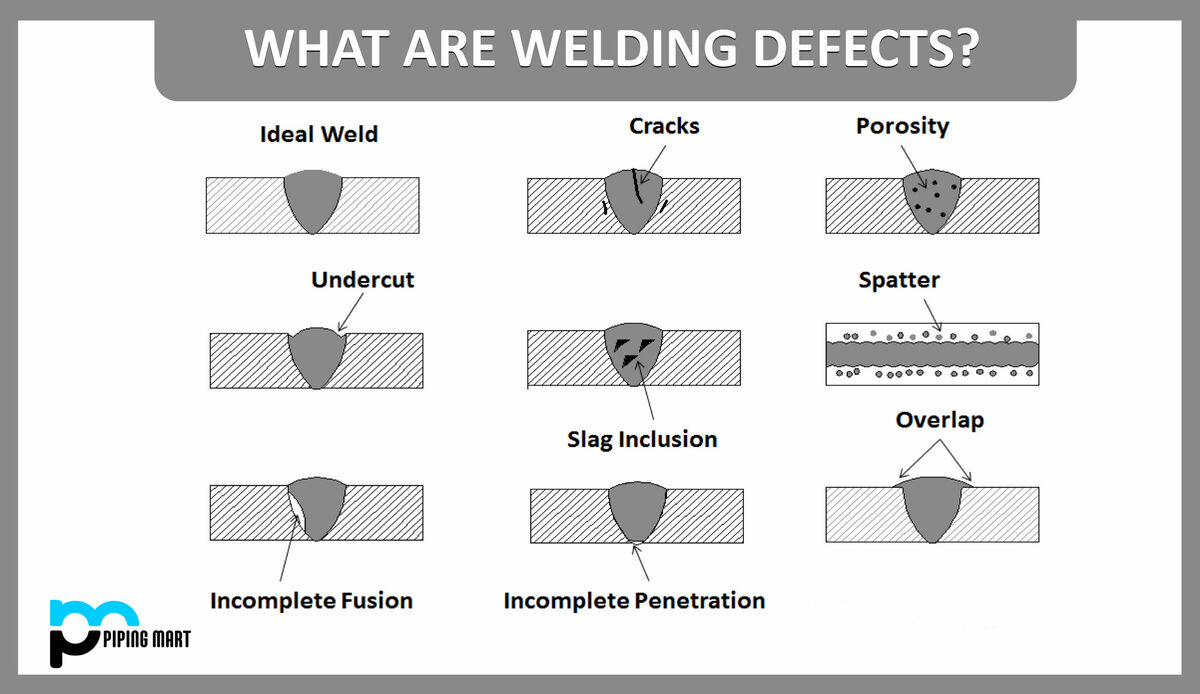

Typical examples are cracks, undercuts, overlaps, porosity, spatter, etc. This occurs when the weld does not adequately cover the base metal. Undercutting is a common welding defects in welding that weakens the strength and stability of welded structures.

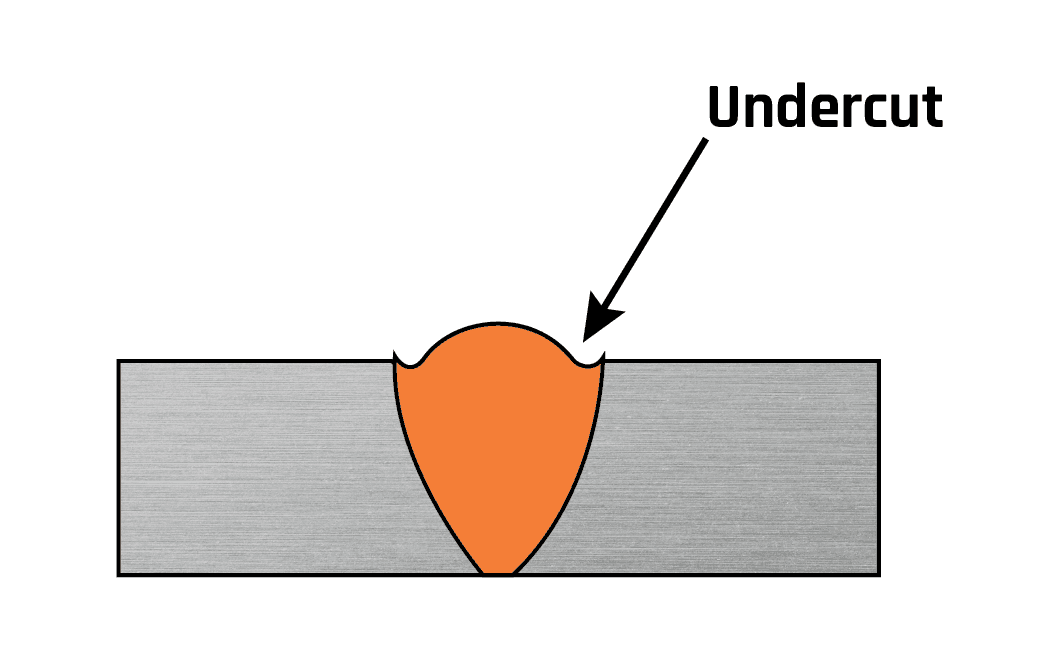

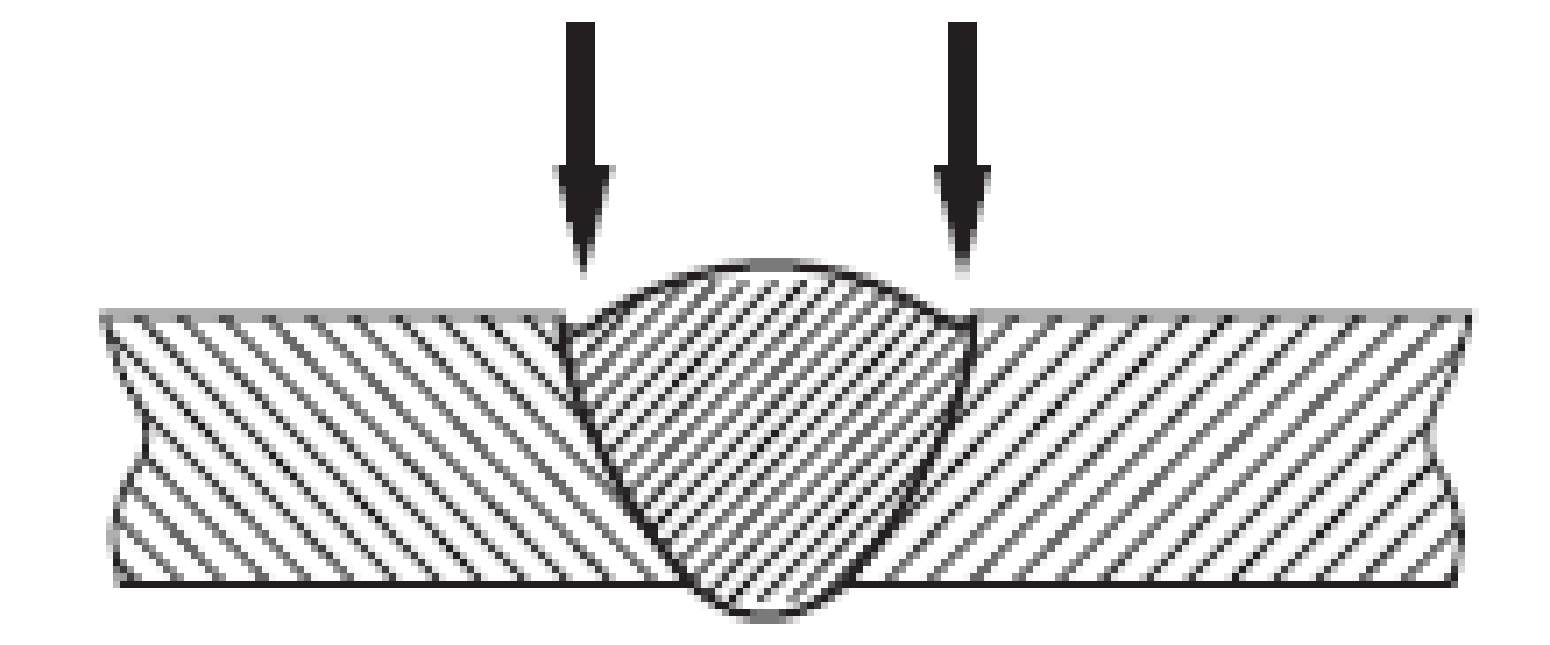

They appear more frequently in fillet and butt joints. Undercutting in welding is a weld defect usually characterized by a groove formation at the weld toe, this occurs when the free edges of the weld metal or base. This type of defect reduces the strength of.

Then, how can it occur? Undercutting is a groove or depression that forms at the base of the weld joint. Undercut is considered as a defect on welding tests.

Undercut is a welding defect that occurs when the base metal is melted or heated too much or too quickly by the welding process. In this article, we delve into the essential. The stem detector imaged the stacking fault defects, offering the opportunity for both tem lamella quality verification and detailed characterization of the stacking faults.

China appears to be keeping its distance as russia and north korea move closer to each other with a new defense pact that could tilt the balance of power among. It is a groove or depression that forms along the edge of the. This defect, characterized by a groove or depression along the weld's edge, can weaken connections and promote corrosion.

Like all other defects, instead of improving the joint. Updated 4:57 pm pdt, june 20, 2024. Undercuts are welding defects that present themselves as irregular narrow grooves on the parent metal.

Cap undercut is a weld defect that requires careful attention to welding parameters, technique, and interpass cleaning to prevent. Undercuts are grooves along the underlying metal surface in a welded joint. An undercut welding defect may occur for such reasons.

This flaw could significantly weaken. One of the most common complications in welding is an undercut, creating weld defects that are unpleasant to the eye and weaken the joint. An undercut is a surface and subsurface defect resulting from grooves within the parent metal area.

Menendez defense tries to undercut ‘super weird’ story about a bell and his wife the bell stood out in a trial that has turned in many ways on the. So, how does undercutting occur in welding?. Although there is a small tolerance for it according to some welding inspectors, usually no undercut is.